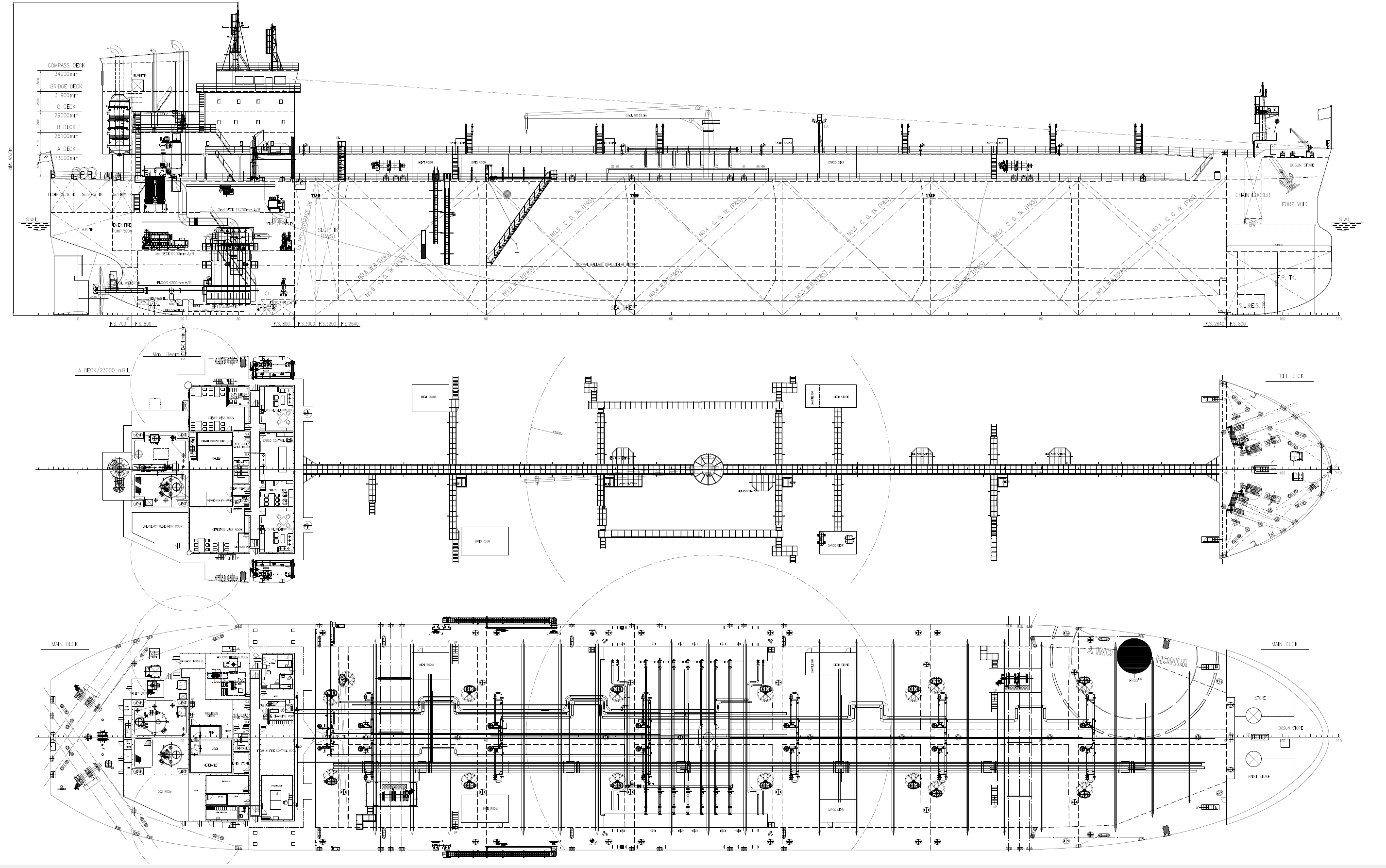

50000DWT Oil & Chemical Tanker

The Vessel to be designed and built as a single screw motor driven tanker for worldwide service transporting product oil and chemical liquid cargo with special coated cargo tanks and slop tanks. And the vessel is designed for

- One complete flush upper deck with forecastle;

- All accommodation including navigation bridge and propulsion machinery to be located aft;

- The cargo area with double side and double bottom to be divided into twelve (12) cargo oil tanks and one (1) pair of slop tanks by center longitudinal bulkhead and transverse bulkheads which are corrugated type;

- The discharge time to be designed about 16 hours at design criteria with six (6) cargo pumps running simultaneously, excluding stripping;

- Focus on Maximum deadweight, capacity and fuel energy efficiency with combination of duct and propeller cap fin;

- EEDI phase 3 compliance;

- Scrubber ready;

LR +100A1, Double Hull Oil and Chemical Tanker, CSR, ESP, Ship Type 2, ShipRight (ACS(B), CM), *IWS, LI, +LMC, UMS, BWTS, IGS, With the descriptive notes “ShipRight (BWMP (T,S), SCM, IHM, SERS, EGCS-R(A,S), GR(ML,A) Main engine capable for future retrofit purpose)”

Or other class equivalent.

Composite boiler Oil fired section abt. 1500kg/h;

Exh. Gas section abt. 550kg/h

Lubricating oil purifier abt. 1600l/h (SAE30) x 2

The vessel is to be suitable for carrying six(6) grades(excluding slop tanks) of clean and dirty petroleum products(MARPOL 73/78 Annex Ⅰ) and chemical liquid cargo(IMO X, Y, Z that suitable for ship type 2&3) in bulk. the flash point of liquid cargo is less than 60℃.

The intended cargoes included as follows:

- Black& white oils(specified on MARPOL ANNEX Ⅰbut only in accordance with the Specification) such as Oils(crude oil not included) and Oil products but excluding asphalt solutions, clarified and Road Oil;

- Liquid Chemicals (specified on CH.17&18 of IBC but only for ship type 2&3 which should be in accordance with the Specification) such as MTBE (Methyl Tert-Butyl Ether) and Caustic Soda (Sodium Hydroxide Solution) (S.G.=1.54) and Ethanol;

- Other liquid chemicals (excluding cargoes not compatible with tank arrangement and scantlings, materials and material protection as specified by the Specification & cargoes which require special equipment and carrying capabilities not provided and not defined in the specification)

- Intelligent Management System;

- Methanol Ready.